It is important to protect touch screens as phones don’t function properly if their screen are damaged.

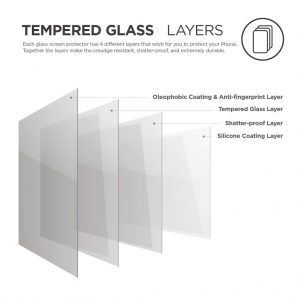

Tempered Glass: Tempered glass is about four times stronger than "ordinary," or annealed, glass. Its made by heating the glass and then cooling it very quickly. It breaks differently than normal glass. A tempered glass screenguard is a multi-layered screen protector.

a) Oleophobic Coating: protect against fingerprints, smudges, oils and over lubricants.

b) Tempered glass

c) Shatter-Proof layer

d) Silicone layer: In case of damage of the tempered glass it keeps small pieces from falling out .

There is an Additional layer of Protective membrane to protect the glue from dust. All these layers make tempered glass up to five times stronger than normal glass.

Process how its made:

a) Glass is purchased in big sheets. Each big sheet is cut in to rectangular pieces.

b) CNC Machine is used to cut to the big sheets to the designed size of phones. The 2.5 D edge curve is also formed at this step.

c) The glass is then examined for imperfections that could cause breakage at any step during tempering. An abrasive such as sandpaper removes sharp edges off the glass.

d) The glass is washed to remove any grains or dirt deposited.

e) After washing it begins a heat treatment process in which it travels through an oven containing a Potassium Salt (KCl) at ~600 °C (Industry standard is 620 °C) for 6-7 hours. The glass then undergoes a high-pressure rapid cooling procedure called "quenching" causing the outer surfaces of the glass to cool and contract faster than the center giving the tempered glass its strength.

Finally the Tempered Glass which we see often in the mobile shops is manufactured like this.

What Is 9H Hardness in Tempered Glass?

9H Hardness refers to the screen not getting scratched by a 9H pencil, the toughest of all standard pencils. This strength can be reached only if the heating lasts for at least 6-8 hours. Some manufactures try to save time and cut this process to 3-4 hours. As a result the glass does not reach required toughness.

So till now we have understood about how the tempered glass is made and the next time if we purchase a tempered glass for our mobile, we will ensure it should have "9H hardness" mentioned on its cover.

Gorilla Glass:

We all have heard the term Gorilla Glass. Corning® Gorilla® Glass is used in the mobile smartphones, tablets, slates, notebooks, wearables and tablets. It has been in the market from past several years and is present in 6 billion devices across 45 major brands. Its a relatively perfect fit for touch-screen handsets. But do you actually know what's special about it? Lets check:

The reality is that its not made of Gorillas. Most modern device manufactures use Corning's Gorilla Glass for protecting their devices touch. Its manufactured by the brand Corning. Objective of Gorilla Glass is to make the cell phone devices getting slimmer, lighter, curvier & durable.

Its main benefits are:

a) Crystal Clarity.

b) Easier to Clean.

c) Highly Scratch Resistance.

d) Harder to Break.

e) Thinner.

f) Flexible to a certain degree.

Process how it is made:

a) The process begins when raw materials are blended into a glass composition and melted.

b) This molten glass is drawn down to form a continuous sheet of flat glass that is so thin & is measured in microns. The glass is untouched by human hands or anything else that will introduce flaws into the surface.

c) The glass sheet is now drowned into hot molten solution of Potassium Salt at ~ 400 °C. This process leaches small sodium ions out of the glass and replaces them with larger potassium ions. During this process as the glass sheet cools, the large particles squeeze the sheet inwards from outside, producing compressive stress on the surface of the glass.

d) Finally these large Potassion Ions are pressed together, producing a layer of compressive stress on the surface of the glass which makes it more resistant to damage and we get Gorilla Glass.

Compressing the surface of the glass makes it stronger and helps to resist scratches and breakproof at a certain degree. In order to break a Gorilla Glass screen, a flaw would have to penetrate through the compressive layer and the tension layer.

Versions of Gorilla Glass:

- Gorilla Glass 6

- Gorilla Glass 5

- Gorilla Glass 4

- Gorilla Glass 3

- Gorilla Glass

- Gorilla Glass DX, Gorilla Glass DX+

- Antimicrobial Gorilla Glass

- Vibrant Corning Gorilla Glass

Popular Devices using Corning Gorilla Glass: Samsung Galaxy S9, Samsung Galaxy S9+,OnePlus 6 and many other devices.

Recent Update by Corning:

On JULY 18, 2018 Corning Incorporated announced two additions of cover glass innovations - Corning® Gorilla® Glass DX and Corning® Gorilla® Glass DX+. Both of these feature an antireflective property that vastly improves optical clarity and superior scratch resistance while maintaining the legendary toughness and touch sensitivity of Gorilla Glass.

It depends entirely on you. Gorilla Glass won't protect your device from everything and is hard enought but still could break. But it will add a layer of tempered glass protection for your phone, which, in turn, will help avoid costly screen repairs of replacing the touch. After all, it is easier (and cheaper) to replace a tempered glass protection compared to a gorilla glass display.

Read More about Tempered Glass: Click Here

Thanks a ton for reading my above blog.

Next Blog: Paytm's Made In India AI Cloud; Amazon, Google oppose Data Localisation!

Ajey Kumar Gupta

(Microsoft Exchange Admin).

0 comments:

Post a Comment